About Us

Sharvik Integra provides custom molding services to businesses serving various industries like Automobile, Industrial electronics, Industrial electrical , Defense, Refrigeration and many more.

We have decades of experience in processing engineering thermoplastics and we like to bring solutions to complex plastic engineering problems using innovative and creative ideas.

We strive to be known in the markets as the best partner for custom plastic injection molding services that operates to the highest ethical standards. Our driving force is our commitment to provide the highest level of customer support, innovation and technical excellence to our clients.

In addition to Moulding services , we also offer mould design and engineering support for new injection molds. We have both in-house and outsourced plastic mold manufacturing resources to provide cost effective solutions.

Our tool room provides routine preventative tooling maintenance and mould repairs to keep customer production running on-time.

Tailored Industry Solutions

We customize our plastic engineering services to meet the specific demands of diverse industries.

Superior Customer Service

We foster strong partnerships with clients, providing continuous support and innovation for lasting success.

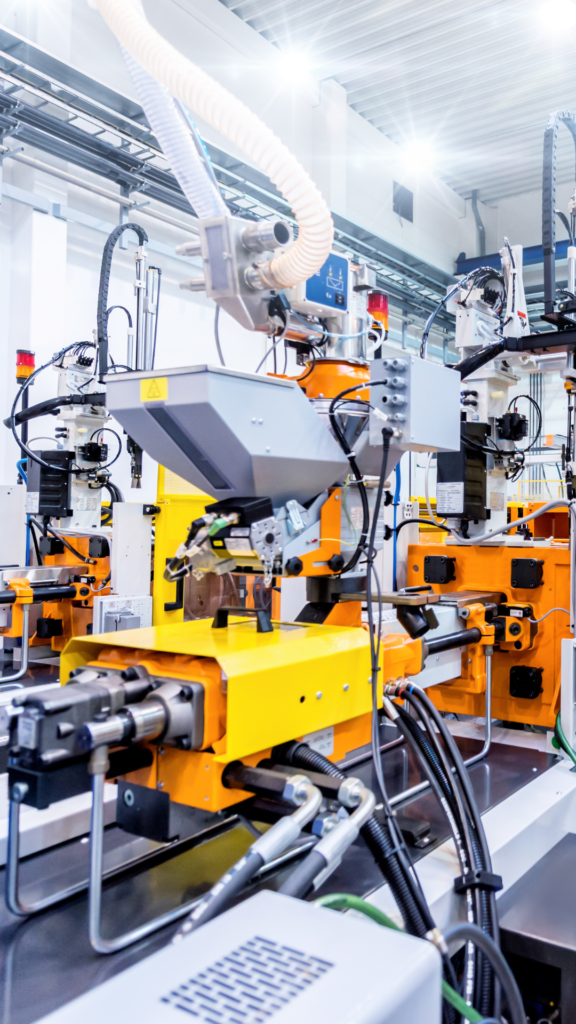

Machinery and Ancillary Equipment

At Sharvik Integra, we leverage state-of-the-art machinery and advanced ancillary equipment to deliver precision-engineered plastic components. Our manufacturing facility is outfitted with cutting-edge technology that ensures the highest quality and efficiency in every project.

Ovens

Tray ovens are used for pre-drying hygroscopic raw materials, ensuring optimal conditions for material processing by removing moisture before molding.

Hopper Loader

Hopper loader facilitates efficient material handling, streamlining the feeding of raw materials into the molding machines.

Mould Temperature Controller

Oil-circulating mould temperature controller maintains precise mould temperature control during the molding process, ensuring consistent quality and performance of the molded components.

Cooling Tower

FRP (Fiberglass Reinforced Plastic) induced draft cooling tower provides effective cooling for the machinery and molded parts, helping to maintain the necessary mould cooling for optimal operation.

Ultrasonic Welding Machine

In-house facility uses ultrasonic technology to weld plastic components with precision, enhancing the durability and quality of the final product.

Runner Grinders

Runner grinders are used to reprocess and recycle runners and sprues, reducing waste and contributing to cost-efficiency in production. Grinders are used for efficient size reduction of scrap generated during moulding operation. This ensures cleanliness & good housekeeping on the entire shop floor.

Advanced Facilities and Measurement Tools”

Our manufacturing facility features reliable power backups and advanced tools to ensure uninterrupted operations.

Gensets

A diesel generator sets are available to power the factory in the event of extended power outages, ensuring uninterrupted production.

Quality & Maintenance Setup

Our dedicated tool room is equipped for mold maintenance and machine upkeep ensuring the longevity and performance of our tools and equipment. Our ability to perform post moulding operations on ports manufactured inhouse ensures seamless quality control & customer service.

Measuring Instruments

Various sizes of vernier calipers, manufactured by Mitutoyo or Baker, are used for accurate measurement of dimensions and tolerances in the toolroom.

Precise Measurements

A range of micrometers and feeler gauges are available for precise measurement and regular tool room activities, supporting meticulous quality control.

Contact Us

Here\’s how you can contact us for any questions or concerns.

Sharvik integra, S. No. 31, Haveli, Ingle Industrial Estate, Tal, Shivane, Pune, Maharashtra 411023

+91 98220 49873

info@PUpanellocks.com

Send Us a Message

Send us a message for any questions or just say hi!